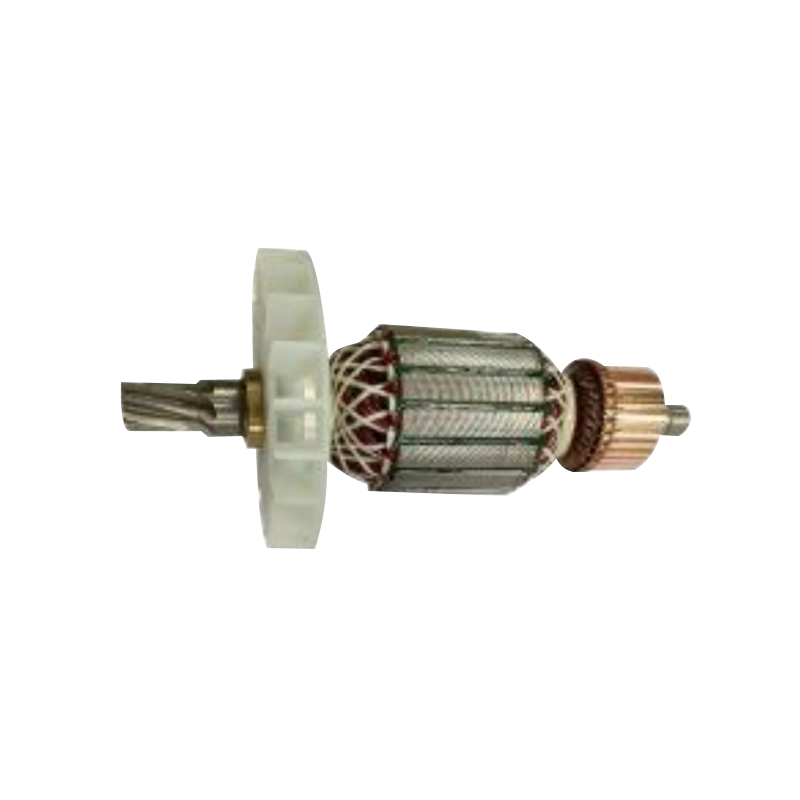

An electric chainsaw motor is a power source designed to drive the cutting chain of a chainsaw using electricity. Unlike gas-powered chainsaws, electric chainsaws rely on an electric motor that provides instant torque and requires less maintenance. These motors are typically quieter, lighter, and more environmentally friendly, making them ideal for residential use and light to medium-duty cutting tasks. They are powered by either a corded connection or a rechargeable battery, offering convenience and ease of use.

Features and Applications of Electric Chainsaw Motors

An electric chainsaw motor is a crucial component that powers the chainsaw, providing the necessary force to rotate the cutting chain around the guide bar. This type of motor operates using electrical energy, which can be sourced from either a corded power supply or a rechargeable battery. Electric chainsaws are increasingly popular due to their ease of use, quieter operation, and reduced environmental impact compared to traditional gas-powered models.

The electric chainsaw motor is designed to deliver high torque at lower speeds, making it suitable for cutting tasks, such as trimming branches, cutting firewood, or clearing brush. Electric motors also produce fewer vibrations, enhancing user comfort during prolonged use.

Corded electric chainsaws draw power directly from an electrical outlet, providing a continuous and stable power supply. These are ideal for tasks that are close to a power source, as they are not limited by battery life. On the other hand, battery-powered models offer greater mobility, making them suitable for outdoor tasks where access to electricity may be limited. These chainsaws use lithium-ion batteries, which are known for their longer run times and faster recharge capabilities.

Electric chainsaw motors are particularly suitable for light to medium-duty cutting tasks, offering a reliable and convenient alternative to gas-powered chainsaws, especially in residential areas where noise and emissions are a concern.

Applications of Single Phase Air Compressor Motors

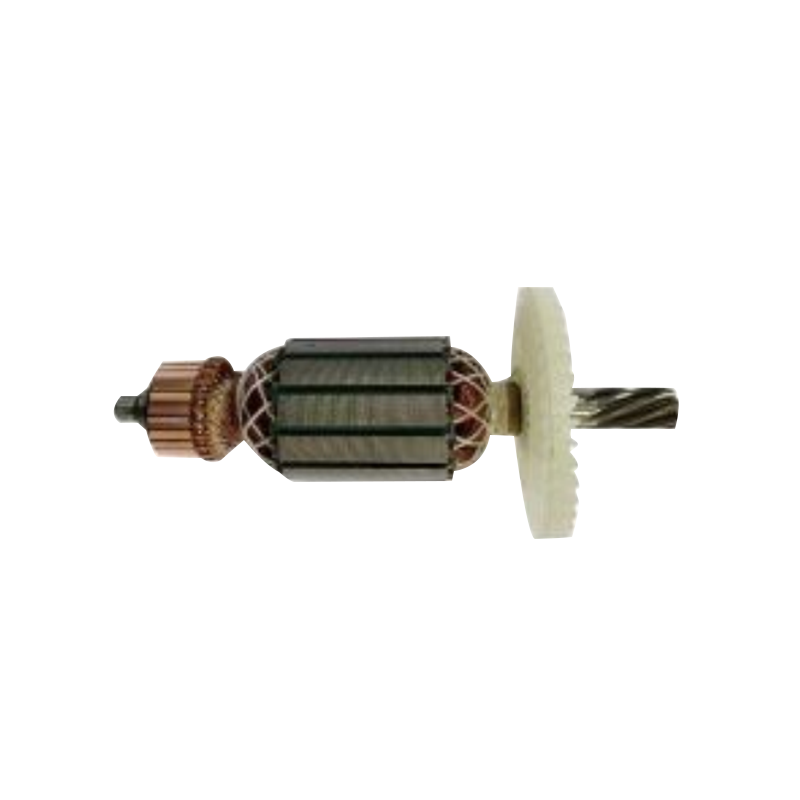

A single-phase air compressor motor is a type of electric motor designed to power air compressors in various residential, commercial, and light industrial applications. This motor uses single-phase electrical power, which is commonly available in more homes and small businesses, making it a versatile choice for powering air compressors used for inflating tires, operating pneumatic tools, or performing other tasks that require compressed air.

The single-phase air compressor motor operates by converting electrical energy into mechanical energy, which drives the compressor pump to generate compressed air. These motors are typically equipped with features like thermal protection to prevent overheating, thereby enhancing their durability and lifespan. They are designed to start under load, which is essential for air compressors that may require a significant amount of torque to get going.

One of the main advantages of single-phase motors is their simplicity and reliability. They require small maintenance and are relatively easy to install, making them an ideal option for smaller air compressor systems. However, they are generally limited to lower power ratings compared to three-phase motors, making them more suitable for light to moderate applications rather than heavy-duty industrial use.

Single-phase air compressor motors are often used in workshops, garages, and small construction sites where portability and ease of use are essential. They offer a cost-effective solution for powering air compressors without the need for complex electrical setups. Additionally, these motors are known for their energy efficiency and can operate effectively on standard household electrical circuits.

Single-phase air compressor motors are dependable, efficient, and widely used in various settings that require moderate air compression capabilities.