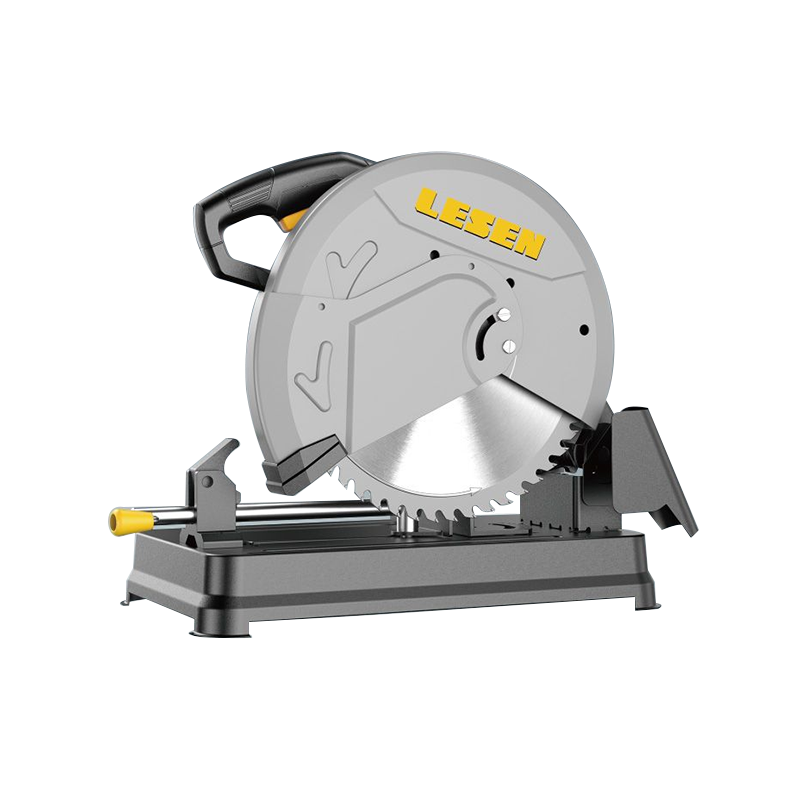

The Metal Cutting Machine is a highly efficient and precise tool designed for cutting a wide range of materials, primarily metal. This machine utilizes a cold cutting technique, which involves cutting materials at relatively low temperatures, as opposed to the high heat generated by traditional saws. This method ensures that the integrity of the material is preserved, making it an ideal choice for industries where precision and quality are paramount.

Key Features and Benefits

Precision Cutting:

High Accuracy: The Metal Cutting Machine is engineered to deliver exceptional cutting accuracy. It utilizes a rotating saw blade, which ensures that cuts are made with deviation from the intended line. This precision is crucial for applications that require tight tolerances and exact measurements.

Clean Edges: The cold cutting process produces clean, burr-free edges, reducing the need for additional finishing work. This feature is particularly beneficial for applications where surface quality is critical.

Enhanced Material Integrity:

Heat Generation: Unlike traditional cutting methods that generate significant heat, the Metal Cutting Machine operates with heat, preserving the material's properties. This reduces the risk of warping or altering the material's mechanical characteristics.

Reduced Thermal Stress: The low-temperature cutting process thermal stress on the material, ensuring that it retains its original strength and durability. This is especially important for materials that are sensitive to heat.

Efficiency and Productivity:

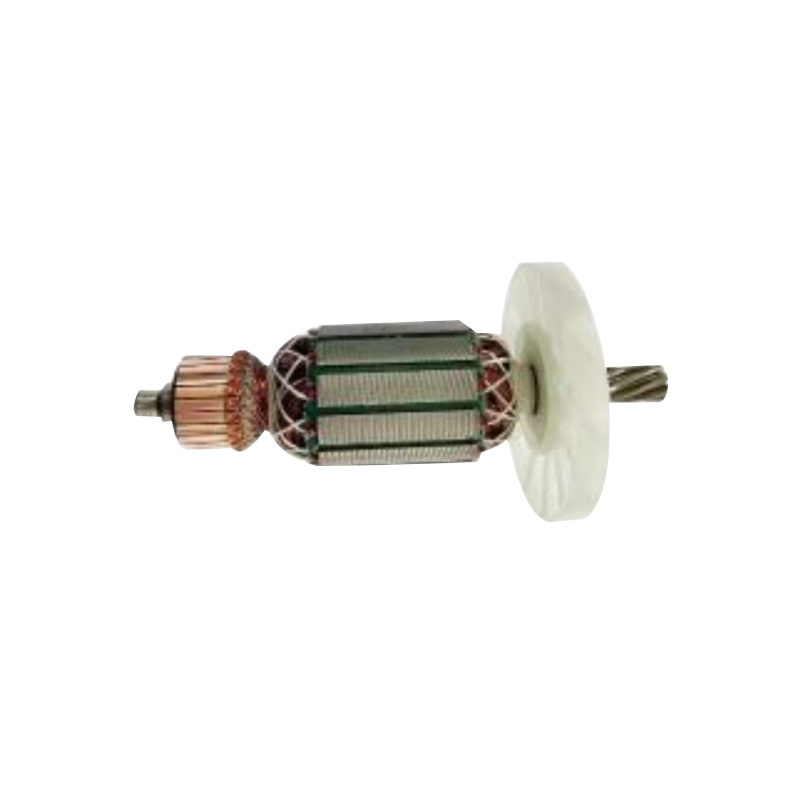

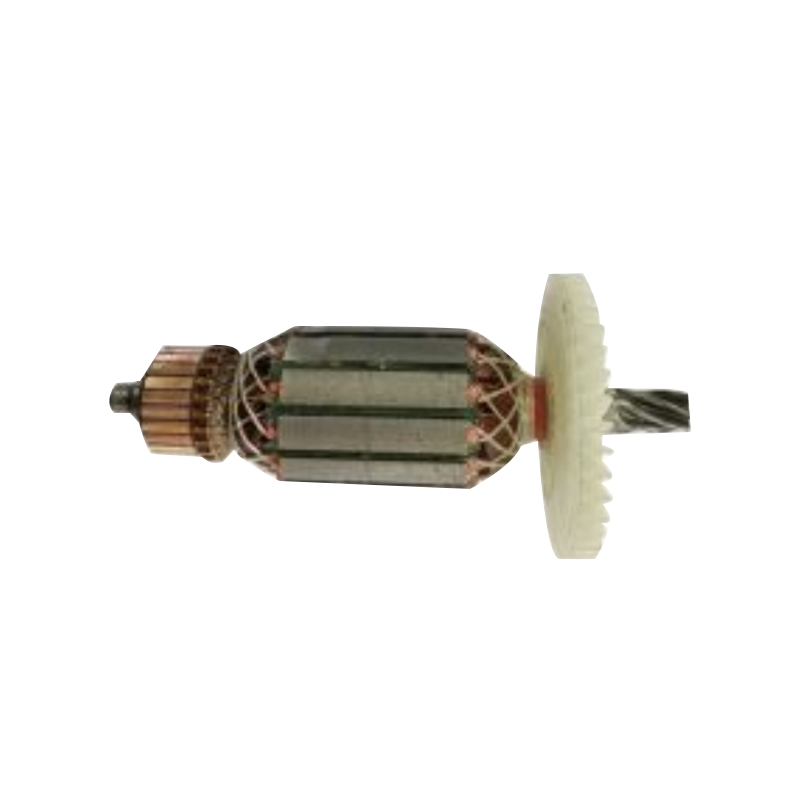

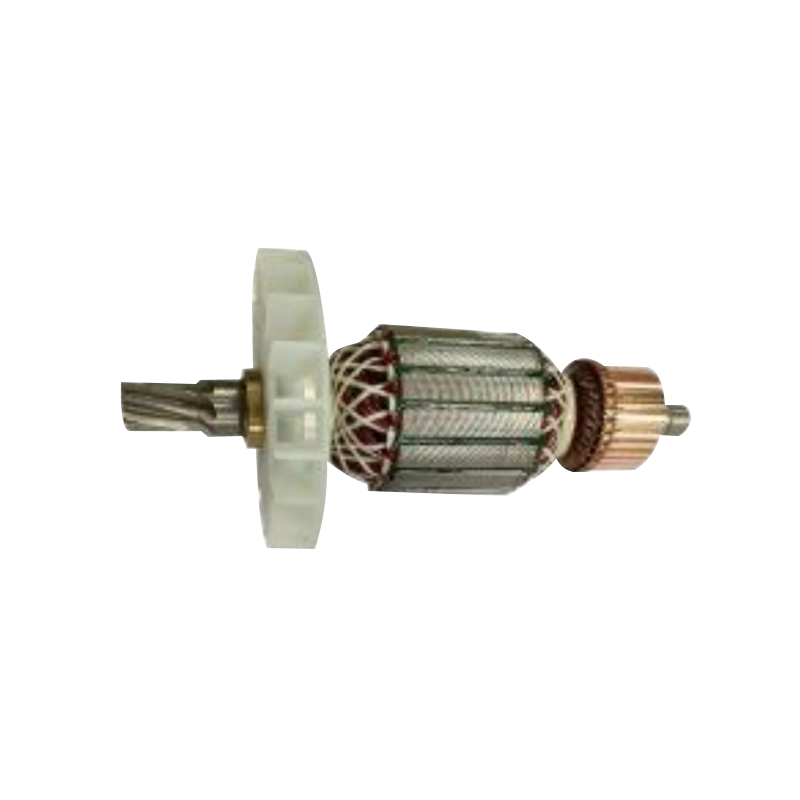

Fast Cutting Speed: The Metal Cutting Machine is designed for high-speed cutting, which enhances productivity and efficiency in the workplace. Its robust motor and sharp blade ensure that materials are cut quickly and accurately.

Automatic Features: Many models come with automatic feed systems and programmable controls, allowing operators to set precise cutting parameters and achieve consistent results with minimal manual intervention.

Versatility and Adaptability:

Wide Material Compatibility: The Metal Cutting Machine is suitable for cutting a variety of materials, including steel, aluminum, brass, and other metals. This versatility makes it a valuable tool for different industrial applications.

Adjustable Cutting Angles: The machine often features adjustable cutting angles, enabling users to perform various cutting tasks, such as straight cuts, miter cuts, and compound cuts. This adaptability adds to the machine’s utility in diverse projects.

User-Friendly Operation:

Intuitive Controls: The Metal Cutting Machine is equipped with user-friendly controls that make it easy to operate, even for those with experience. Features such as digital displays and programmable settings enhance ease of use.

Safety Features: Safety is a priority with the Metal Cutting Machine, which includes features such as blade guards, emergency stop buttons, and safety interlocks. These features help protect operators from potential accidents and ensure a secure working environment.

Maintenance and Durability:

Low Maintenance: The machine is designed for minimal maintenance requirements, thanks to its durable construction and reliable components. Regular upkeep is straightforward, involving basic cleaning and occasional blade replacement.

Robust Construction: Built with high-quality materials and precision engineering, the Metal Cutting Machine offers long-lasting performance and reliability, even in demanding industrial settings.

Applications:

The Metal Cutting Machine is widely used across various industries, including manufacturing, construction, automotive, and metalworking. It is ideal for tasks such as cutting metal pipes, tubes, profiles, and bars. Its precision and ability to handle various materials make it suitable for applications ranging from fabrication and assembly to repair and maintenance.

Overview:

In summary, the Metal Cutting Machine is a powerful and versatile tool designed to provide precise, clean cuts with heat generation. Its advanced features, including high-speed cutting, automatic controls, and adjustable angles, make it an invaluable asset in numerous industrial applications. With its user-friendly operation and emphasis on material integrity, this machine stands out as a reliable solution for achieving high-quality cutting results. Whether for high-volume production or custom cutting tasks, the Metal Cutting Machine delivers efficiency, accuracy, and durability, making it a crucial component in modern manufacturing and metalworking environments.