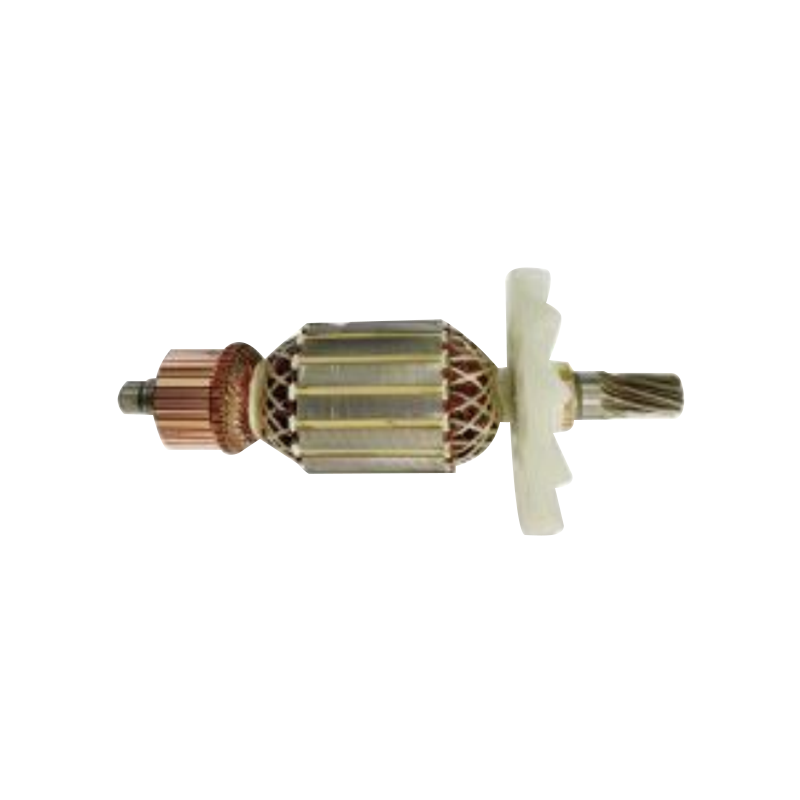

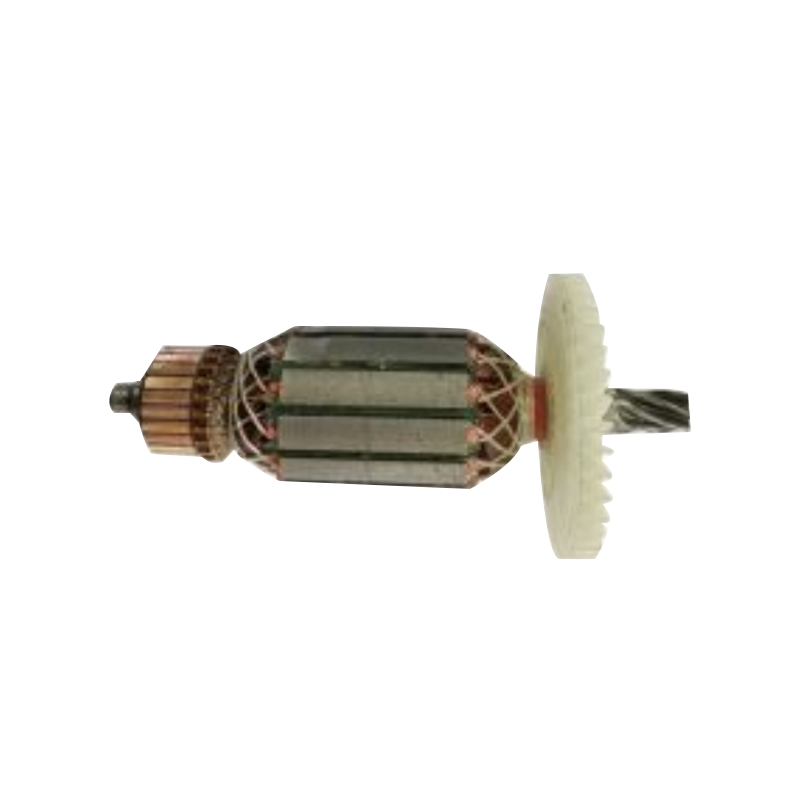

The Cut Off Machine stands as a cornerstone of precision and efficiency in industrial manufacturing and fabrication. Designed to handle a wide array of metal types and thicknesses, this robust equipment offers unmatched accuracy and durability, making it an indispensable tool in various applications.

Product Description:

At its core, the Cut Off Machine is engineered for high-performance cutting tasks, tailored to meet the rigorous demands of modern manufacturing processes. This machine features advanced technology to ensure clean, precise cuts with minimal burrs and deformation. It is capable of processing metals such as steel, aluminum, copper, and brass, accommodating diverse industry requirements from automotive to aerospace.

Key Advantages:

Precision Cutting:

Accurate Measurements: The machine integrates sophisticated control systems and cutting mechanisms that guarantee precise measurements and accurate cuts, reducing material waste and enhancing overall efficiency.

Consistent Quality: With its advanced settings, users can achieve uniform cuts across different batches, ensuring consistency and high-quality results for every project.

Versatile Functionality:

Multiple Cutting Modes: Equipped with various cutting modes, the machine can handle both straight and curved cuts, adapting to different design specifications and production needs.

Adjustable Settings: It offers adjustable speed and pressure settings, allowing operators to customize the cutting process according to the type of metal and the required cut quality.

Durable Construction:

Heavy-Duty Build: Constructed from high-grade materials, the machine is designed to withstand the rigors of continuous operation and heavy workloads, ensuring longevity and reliability.

Low Maintenance: The machine’s durable components and efficient design contribute to reduced maintenance needs and extended operational life, downtime and operational costs.

Product Features:

Advanced Control System:

User-Friendly Interface: The machine features an intuitive control panel that simplifies operation and setup, allowing users to program and monitor the cutting process with ease.

Automated Functions: Automation capabilities enhance productivity by reducing manual intervention and streamlining the cutting process, leading to faster turnaround times and improved efficiency.

Enhanced Safety:

Protective Measures: Equipped with safety guards and emergency stop features, the machine prioritizes operator safety and prevents accidents during operation.

Low Noise Operation: Designed to operate with noise, it provides a safer and more comfortable working environment.

Energy Efficiency:

Optimized Performance: The machine’s design ensures energy consumption, reducing operational costs and contributing to a more sustainable manufacturing process.

Eco-Friendly Features: Incorporating eco-friendly technologies, the machine waste and environmental impact, aligning with modern sustainability practices.

Applications:

The Cut Off Machine is widely used across various industries for different applications. In the automotive sector, it is employed for cutting intricate metal components with precision. In construction, it handles the cutting of structural steel and metal sheets. The aerospace industry utilizes the machine for fabricating parts and components that require high accuracy and durability. Additionally, it is valuable in metalworking shops for creating custom metal pieces and prototypes.

Conclusion:

The Cut Off Machine is a critical asset for industries requiring precision metal processing. Its blend of advanced technology, versatile functionality, and durable construction ensures reliable performance and high-quality results. Whether used in large-scale manufacturing or small-scale fabrication, this machine meets the demanding needs of modern metalworking with exceptional efficiency and precision. With its user-friendly controls, safety features, and energy-efficient design, it stands out as a leading choice for professionals seeking to enhance their cutting capabilities and overall productivity.